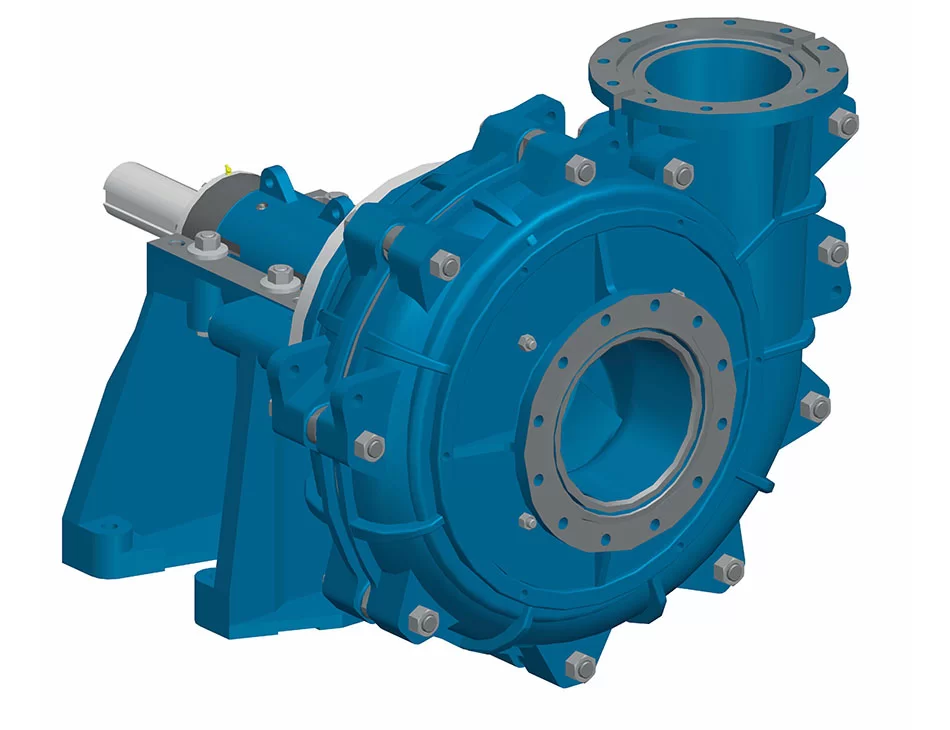

300S-L type slurry pump is a kind of light slurry pump, which is widely used in many industries, such as beneficiation, metallurgy, coal and building materials. It has the structural characteristics of cantilever and horizontal centrifugal slurry pump. The outlet position can be installed and used at 45 ℃ intervals and rotated at eight different angles as needed, which provides great flexibility for on-site installation.

Structural Features

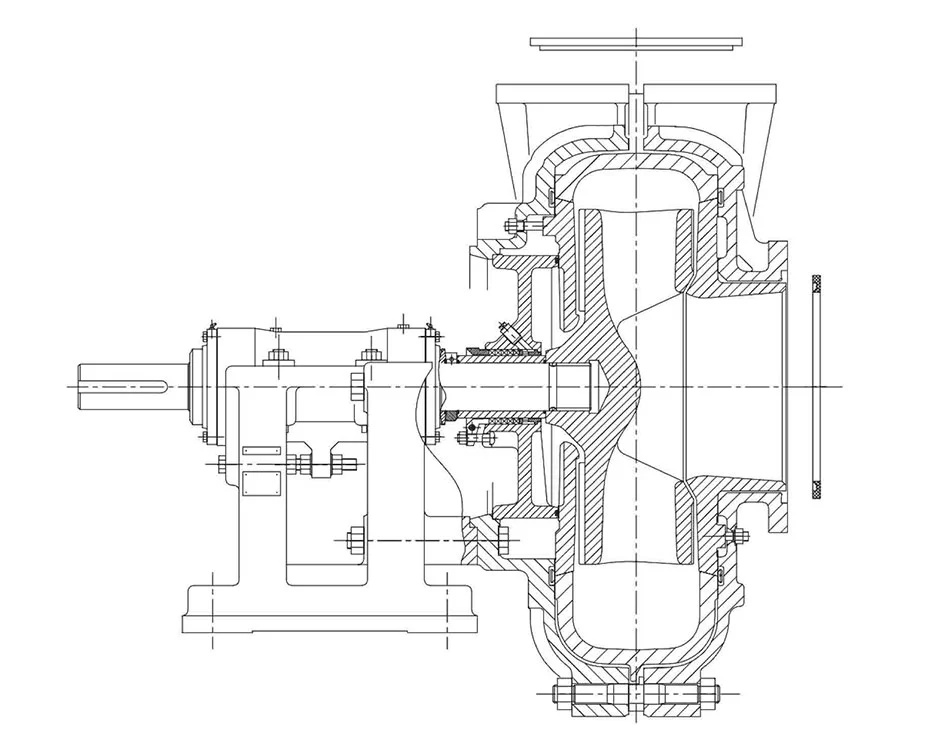

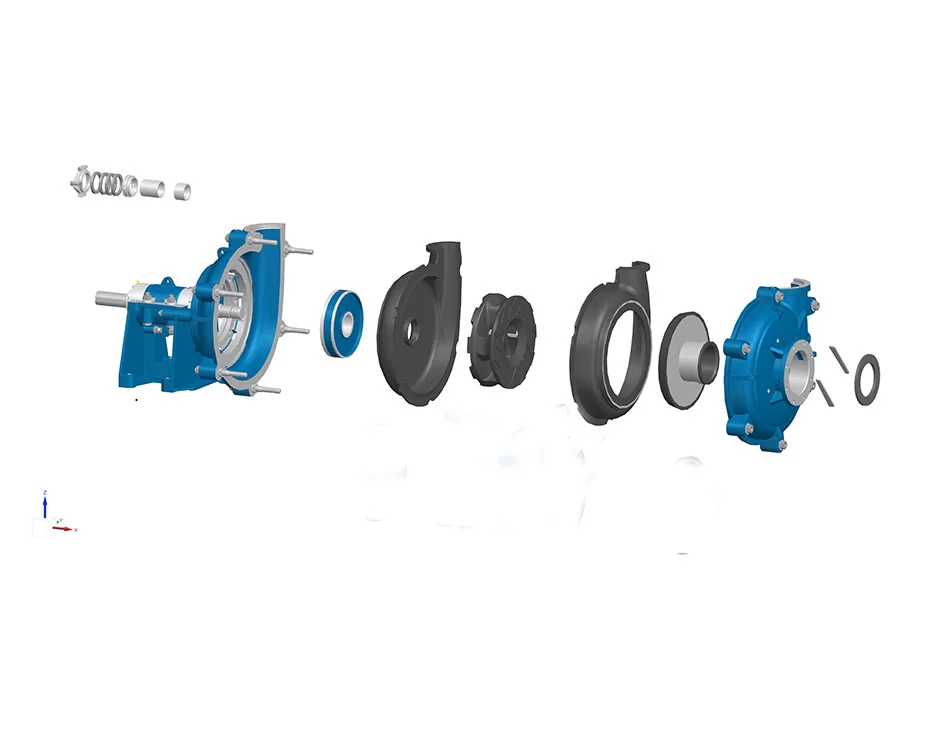

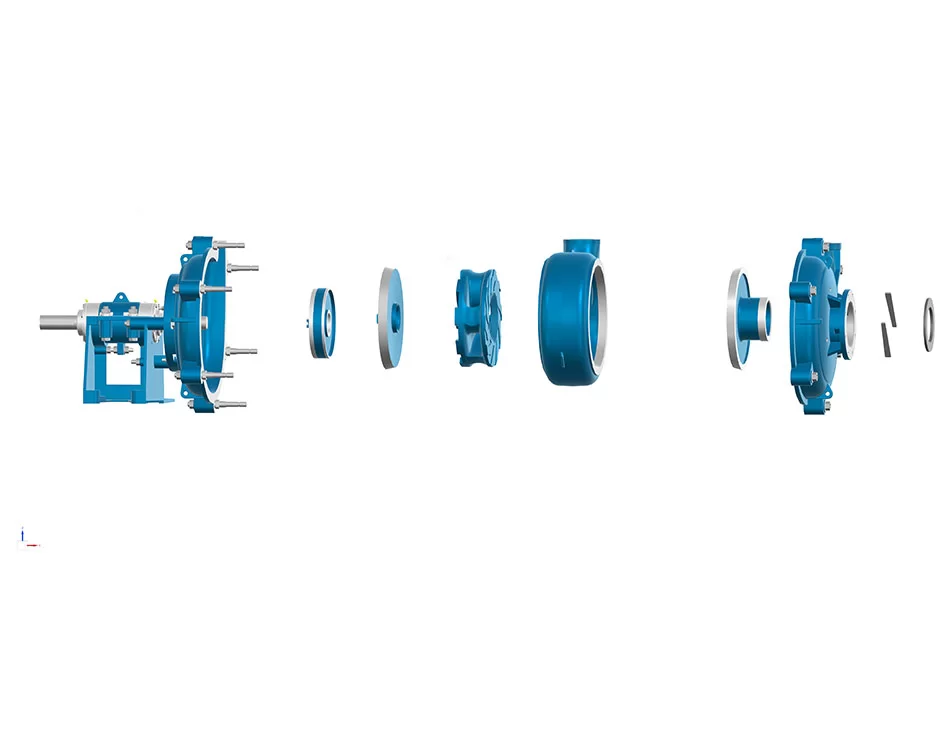

Cantilever Horizontal Design: It adopts cantilever structure, and the overall layout is compact, which is convenient for installation and maintenance.

Rotatable Outlet: The position of the outlet can be installed at eight different angles at intervals of 45℃ according to the needs of the actual working conditions with strong adaptability

Material Features

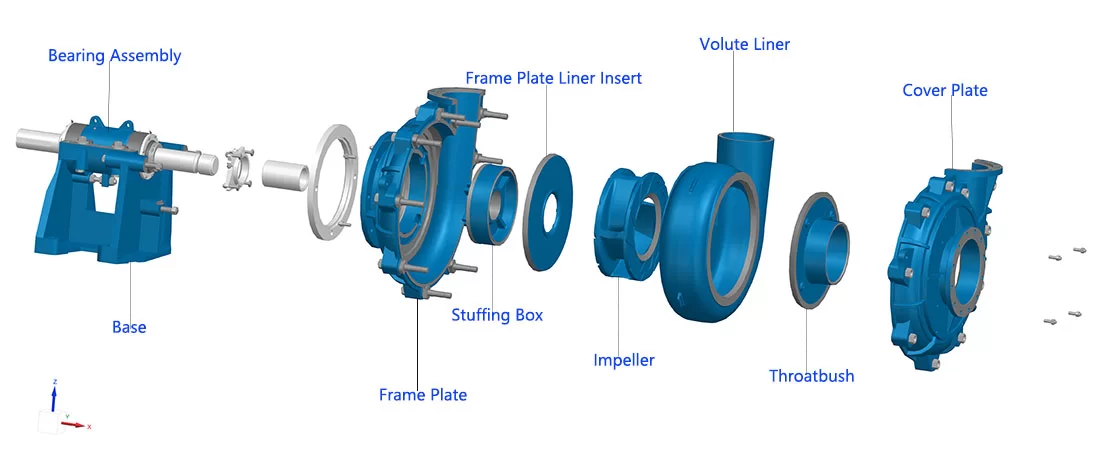

Wear Resistant Liner: The pump body has replaceable wear resistant metal liner or rubber liner, which can effectively resist wear and extend the service life of the pump.

Wet-end Parts: Impellers, Volute Liner, frame plate liner insert and other wet-end parts are made of wear resistant metal or rubber materials. According to the needs of different working conditions, suitable materials can be selected to improve the wear resistance and corrosion resistance of the pump.

Features Of Use

High Speed, Small Volume, Light Weight: Compared with heavy-duty slurry pump, the 200E-M light slurry pump has high speed, small volume, light weight, and more flexible and efficient operation.

Wide Range Of Application: It is suitable for delivering fine particles, low-concentration slurry or corrosive slurry, which can meet the transportation needs under a variety of working conditions. The weight concentration of the conveying slurry generally does not exceed 30%, and it can also be used to transport high-concentration and low-abrasive slurry.

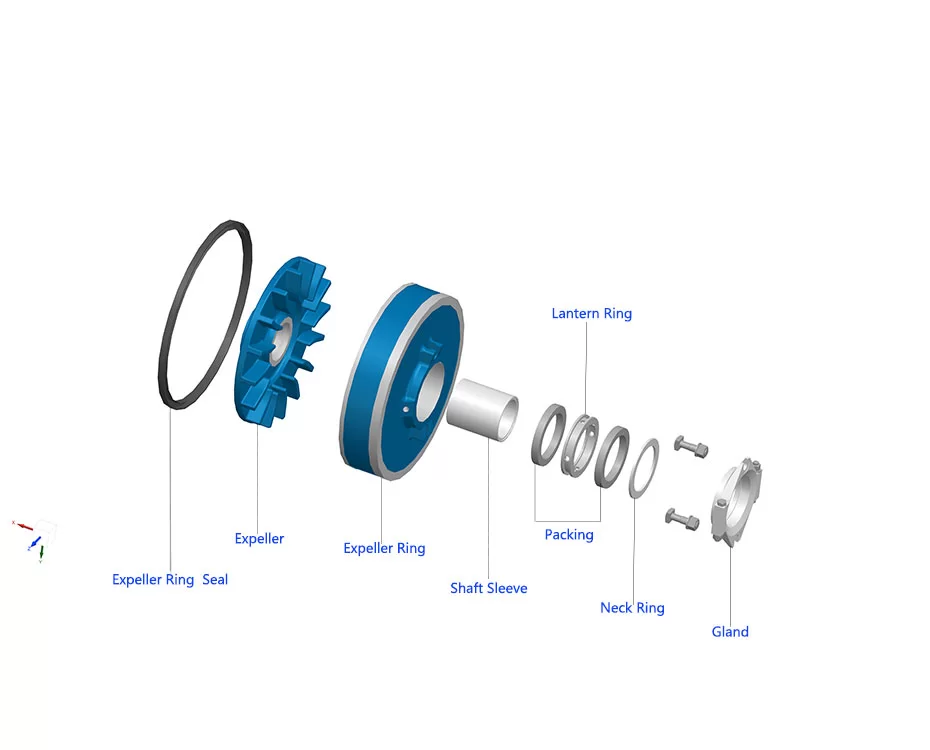

Sealing System

The light slurry pump has a variety of shaft sealing systems, which can adopt packing seals, expeller seals, mechanical seals. Users can choose the most appropriate sealing method according to the specific working conditions and medium characteristics to ensure the reliable operation and sealing performance of the pump.

Drive Models

The pump has a variety of drive models, including DC drive, CR belt drive, ZVZ drive, CV drive and so on. Different drive methods can meet the drive needs of different equipment and working conditions, providing users with more choices and facilitating matching and integration with existing equipment.

DC

CV

ZVZ

CLZ

Model | Allowable | Clear Water Performance |

| |||||

Max. Power | Capacity Q | Head H | Speed n | Eff. η | NPSH | Impeller Dia. | ||

(kw) | m3/h | l/s | (m) | (r/min) | (%) | (m) | (mm) | |

300S-L | 560 | 468-2538 | 130-708 | 8-60 | 400-950 | 79 | 2-10 | 653 |

EXPELELR-SEAL

GLAND-SEAL

Oct 31,25

Slurry pump manufacturer – Part of the mining show booked by CNSME® for 2024

Oct 31,25

How to choose the right shaft seals for your slurry pumps

At present, the slurry pump is one of the indispensable equipment in various technological processes such as ore beneficiation, coal preparation,

Oct 31,25

Similarities and differences between ZJL vertical slurry pump and SP submerged slurry pump

Oct 31,25

CNSME Slurry Pump Company to Participate in Mining Exhibition in Istanbul, Turkey in Early May!

Oct 31,25

Newly manufactured 6/4 DAH slurry pumps

Oct 31,25

Welcome to the Turkey Mining Exhibition: A Gateway to Explore the World of Slurry Pumps!

bscribe newslette

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.