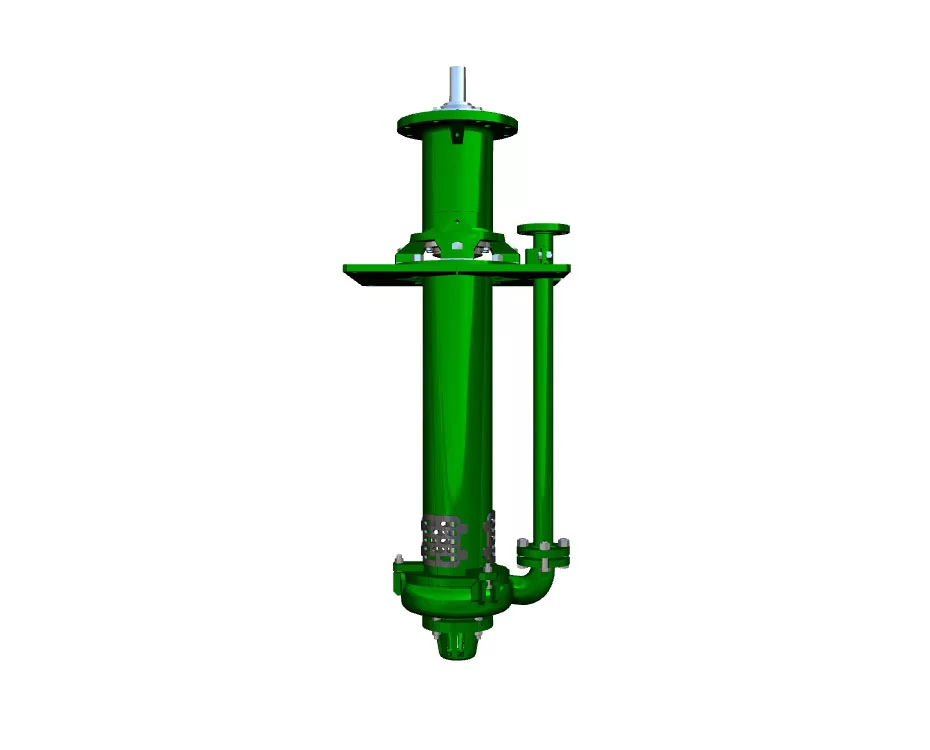

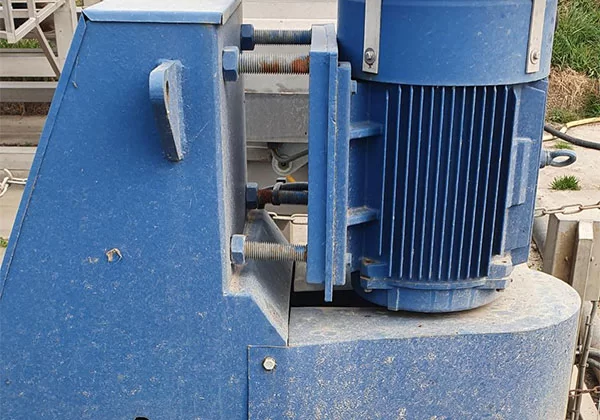

40PV-SP vertical slurry pump is a kind of high efficiency, wear resistant, corrosion resistant centrifugal slurry pump, widely used in mining, electric power, metallurgy, coal, chemical industry, building materials and other industries.The pump adopts vertical multi-stage structure, compact design, small footprint, easy to install and maintain.

Structure Characteristics

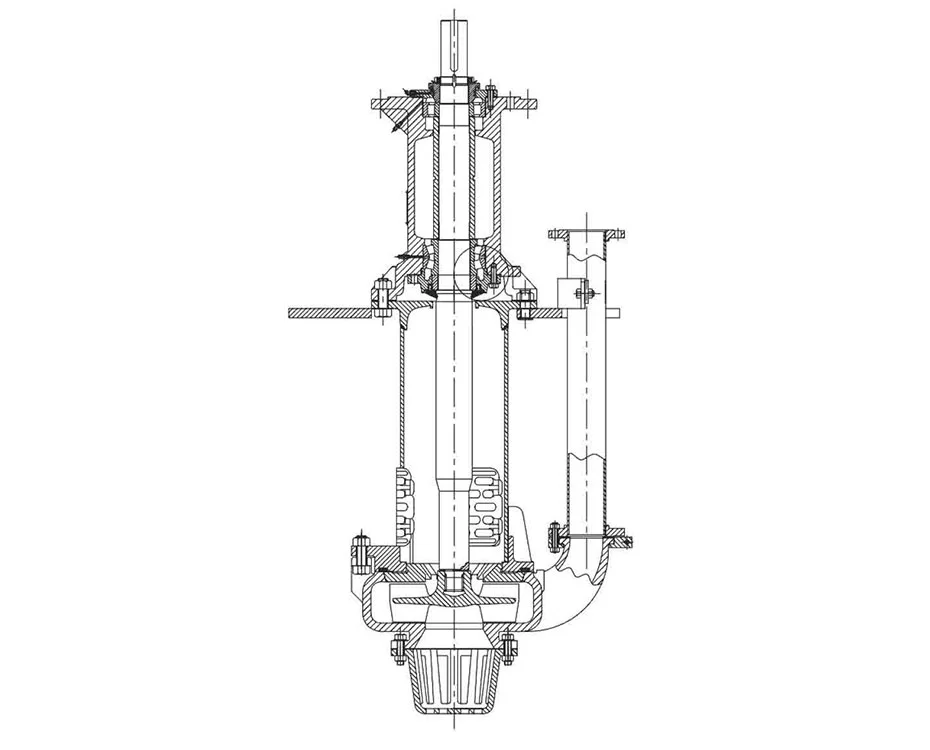

Vertical cantilever type, single pump casing structure: without any shaft seal, immersed in the liquid work, suitable for conveying abrasive, coarse particles, high concentration slurry.

Wear resistant and corrosion resistant materials: the pump casing and impeller are made of wear-resistant and corrosion resistant materials, which can run for a long time under the harsh working environment.

Application

Mining: Pumping slurry, improving the efficiency of ore processing

Metallurgy: Handling high concentration slurry, guaranteeing production continuity.

Coal: Conveying coal slurry in coal washing process, improving coal washing efficiency.

Chemical Industry: Conveying corrosive, coarse particles, high concentration slurry, to ensure production safety.

Advantages

High Head, High Efficiency: Multi level impeller design effectively improves the head and pumping capacity.

Convenient Maintenance: Vertical structure design, no need for shaft seal and sealing water, reducing maintenance costs.

Strong Adaptability: According to the level of the slurry pool, different lengths of pump drive shafts or suction tubes can be selected to adapt to a variety of working conditions.

Reasons for choosing 40PV-SP vertical slurry pump

Advanced Technology: Introducing foreign advanced slurry pump technology with excellent performance.

High Reliability: High chromium cast iron and rubber materials are used to improve the wear resistance or corrosion resistance of the impeller and pump casing.

Environmental Protection And Energy Saving: Low noise and low vibration design to reduce the impact on the working environment.

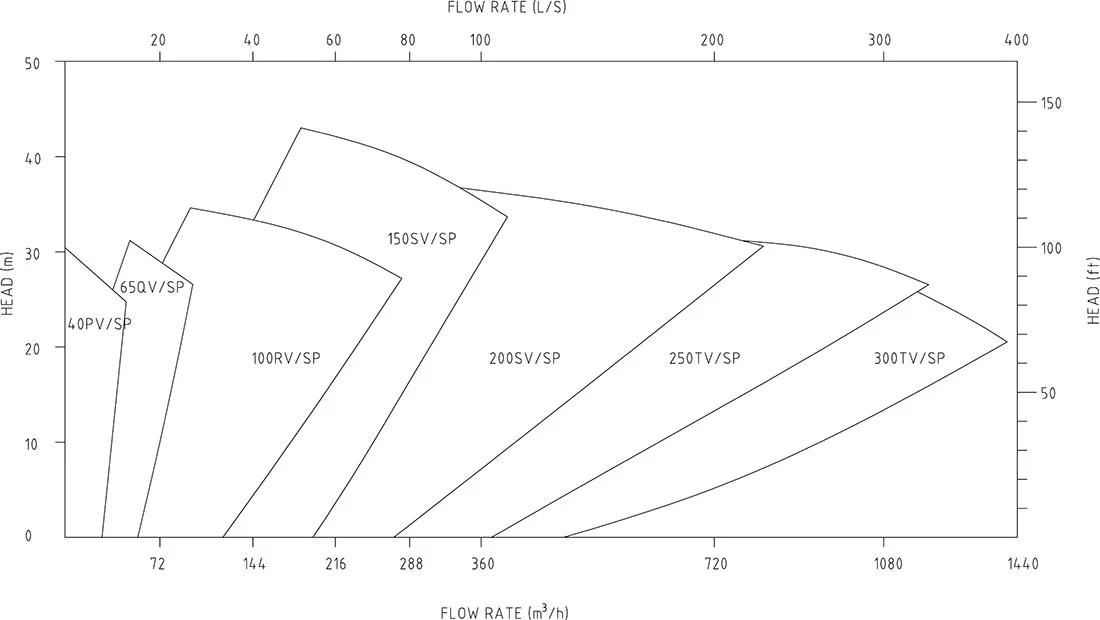

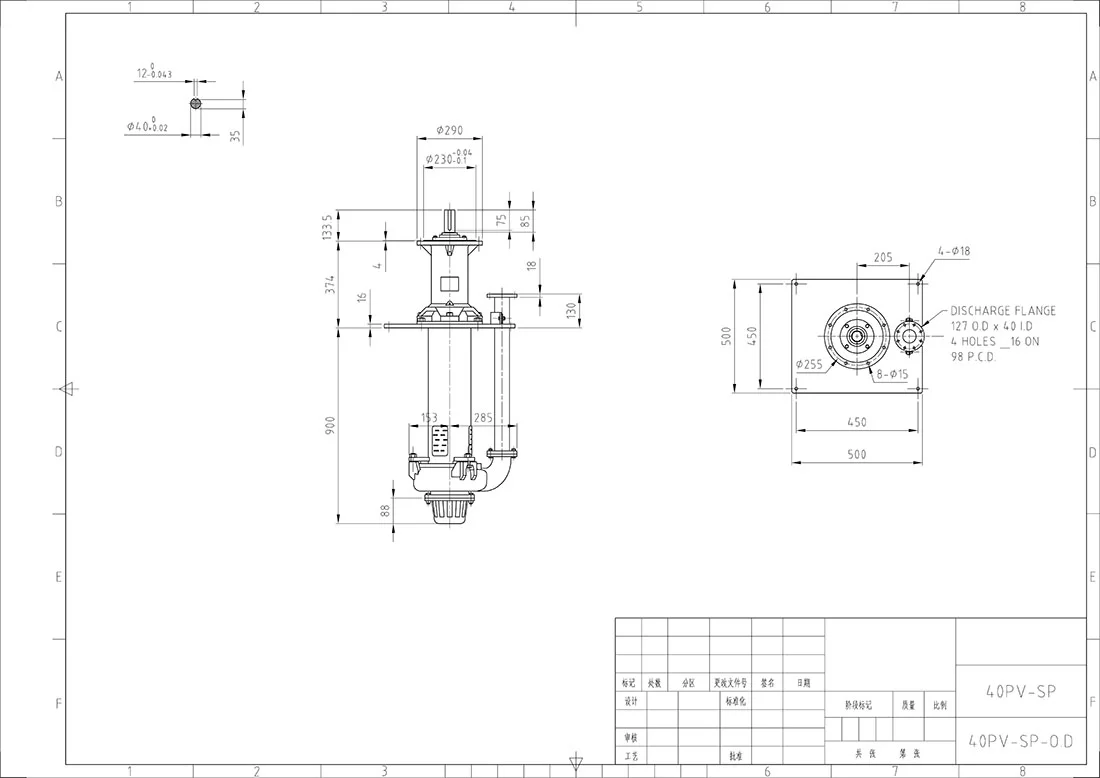

Specifications of SP(R) Series Vertical Slurry Pumps | |||||||||||

Model | Frame | Max. | Sump | Performance for Clear Water | Impeller | ||||||

Capacity Q | Head | Speed | Efficiency | Type | No. of | Vane Φ | Passage | ||||

m3/hr | m | r/min | % | ||||||||

40PV-SP | PV | 15 | 900 | 10–44 | 5–28 | 1000-2200 | 20-40 | Open | 5 | 188 | 12 |

10–40 | 9–37 | 1400-2600 | 15-32 | Cyclo | 8 | 195 | 26 | ||||

40PV-SPR | PV | 15 | 900 | 10–50 | 8–52 | 1200-3000 | 20-40 | Open | 5 | 188 | 12 |

65QV-SP | QV | 30 | 1200 | 20–120 | 4–56 | 600-2000 | 25-51 | Open | 5 | 280 | 15 |

20–110 | 5–28 | 700-1500 | 20-35 | Cyclo | 8 | 290 | 40 | ||||

65QV-SPR | QV | 30 | 1200 | 20–100 | 8–46 | 700-850 | 20-47.5 | Open | 5 | 280 | 23 |

100RV-SP | RV | 75 | 1500 | 50–300 | 6–50 | 500-1400 | 20-56 | Open | 5 | 370 | 32 |

50–250 | 6–31 | 600-1200 | 20-40 | Cyclo | 8 | 390 | 70 | ||||

100RV-SPR | RV | 75 | 1500 | 50–270 | 9–46 | 600-1400 | 30-60 | Open | 5 | 370 | 40 |

150SV-SP | SV | 110 | 1800 | 100–500 | 7–37 | 500-1000 | 20-55 | Open | 5 | 450 | 45 |

100–450 | 7–37 | 500-1000 | 20-40 | Cyclo | 8 | 480 | 80 | ||||

150SV-SPR | SV | 110 | 1800 | 100–450 | 7–35 | 500-1000 | 20-56 | Open | 5 | 450 | 45 |

200SV-SP | SV | 110 | 1800 | 200–800 | 7–38 | 400-850 | 30-64 | Open | 5 | 520 | 65 |

250TV-SP | TV | 200 | 1800 | 300–1000 | 8–35 | 400-750 | 20-63 | Open | 5 | 575 | 65 |

300TV | TV | 200 | 2100 | 360–1400 | 5–28 | 350-700 | 20-62 | Open | 5 | 610 | 65 |

Material Options of Wet end Parts: A05, A33, A49, A61, R55 | |||||||||||

Oct 31,25

Pumps for Limestone-gypsum wet FGD (Flue Gas Desulfurization) Process

Oct 31,25

8 sets of vertical slurry pump SV/100R with pump pulleys, shipped to our customer in Chile.

8 sets of vertical slurry pump SV/100R with pump pulleys, shipped to our customer in Chile.

Oct 31,25

CNSME: Your Trusted Slurry Pump ODM and OEM Provider

Oct 31,25

2024 Chinese New Year holiday notice

Oct 31,25

Welcome to the Turkey Mining Exhibition: A Gateway to Explore the World of Slurry Pumps!

Oct 31,25

Pump knowledge — Minimum operating frequency of slurry pump

As a supplier of slurry pumps from China, we clearly understand that customers have questions about the minimum operating frequency of slurry pumps. In this

bscribe newslette

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.