Key Features

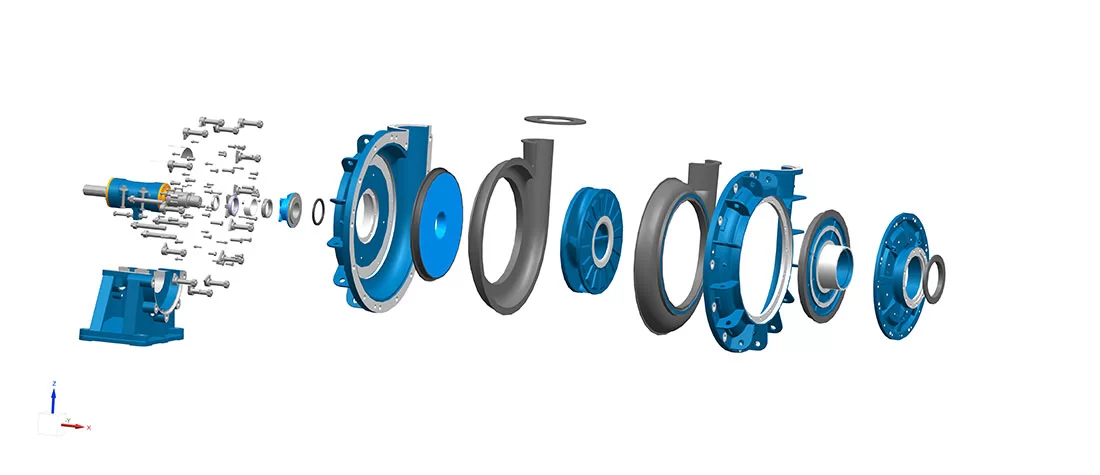

Large diameter, low speed, high efficiency impellers manufactured from a range of abrasion resistant hard alloys provides increased wear life.

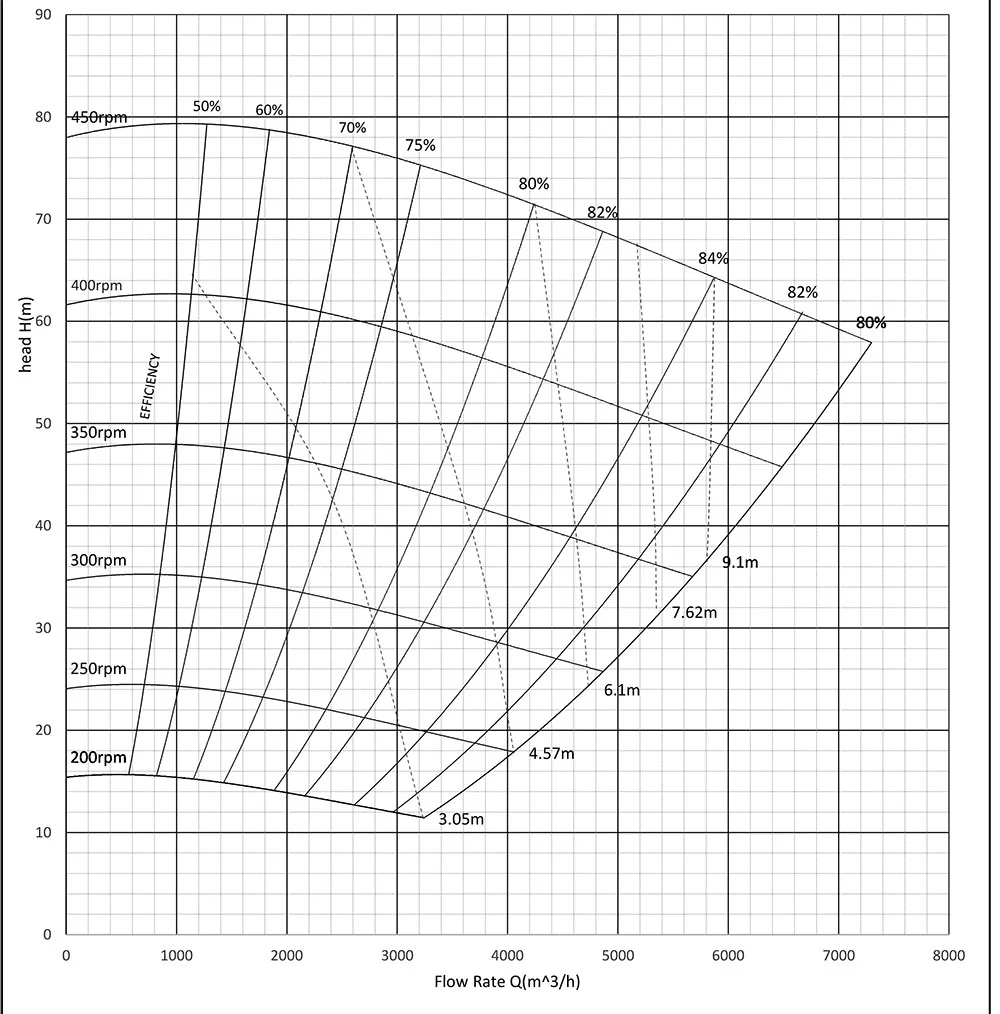

Unique design and excellent hydraulics ensures high performance efficiency

4-vane, large open impeller internal passages allow for larger particle passing

Latest wear resistant materials combination optimizes component performance

Interchangeable metal or elastomer liners provides ease of maintenance

A large diameter shaft with the shortest possible over hang and heavy duty roller bearings housed in a removable bearing box extends bearing life

lmpeller release collar facilitates the impeller removal

Simple full face side liner adjustment allows the liner to move closer to the impeller face to minimize the impeller-throatbush gap and to extend wear life

Fast one-piece wet-end change-out on larger sized pumps ensures minimum mill downtime to save time and money

Available pump body reverse rotations allows for both right vertical (stan-dard] and left vertical (optional) discharge positions to offer plant design flexibility

Pump

Model | A* | B* | C | D | U | Key Size | E | G | H | J* | K | L | M | N | W |

mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm |

125EE-MD | 1200 | 206 | 240 | 457 | 85 | 22×14 | 222 | 378 | 412 | 385 | 384 | 448 | 622 | 240 | 64 |

150EE-MDR(U) | 1247 | 243 | 351 | 457 | 85 | 22×14 | 222 | 533 | 569 | 532 | 554 | 448 | 622 | 265 | 400 |

200FF-MDR(U) | 1670 | 335 | 485 | 610 | 120 | 32×18 | 290 | 725 | 752 | 745 | 740 | 705 | 990 | 383 | 460 |

250DD-MDR(U) | 1742 | 390 | 560 | 610 | 120 | 32×18 | 290 | 824 | 868 | 850 | 847 | 705 | 990 | 399 | 350 |

300GG-MDR(U) | 2010 | 381 | 629 | 851 | 150 | 36×20 | 357 | 940 | 1020 | 879 | 980 | 876 | 1219 | 393 | 870 |

350TU-MDR(U) | 2262 | 404 | 697 | 900 | 150 | 36×20 | 350 | 1030 | 1123 | 970 | 1077 | 1050 | 1460 | 502 | 390 |

400TU-MDR(U) | 2412 | 510 | 801 | 900 | 150 | 36×20 | 350 | 1148 | 1281 | 1156 | 1199 | 1050 | 1460 | 520 | 450 |

450TU-MDR(U) | 2468 | 580 | 930 | 900 | 150 | 36×20 | 350 | 1293 | 1431 | 1207 | 1345 | 1050 | 1460 | 520 | 850 |

550U-MDR(U) | 3180 | 680 | 1025 | 900 | 240 | 56×32 | 455 | 1406 | 1550 | 1322 | 1479 | 1375 | 1440 | 610 | 850 |

650U-MDR(U) | 3343 | 758 | 1200 | 900 | 240 | 56×32 | 455 | 1645 | 1853 | 1554 | 1755 | 1375 | 1440 | 709 | 1200 |

| | | | | | | | | | | | | | | |

* Includes compression of rubber flange joint.

Note: Casing dimensions are symmetrical around vertical centerline if the “left vertical” pump orientation was used |

|

|